Ongoing Projects (Excerpt)

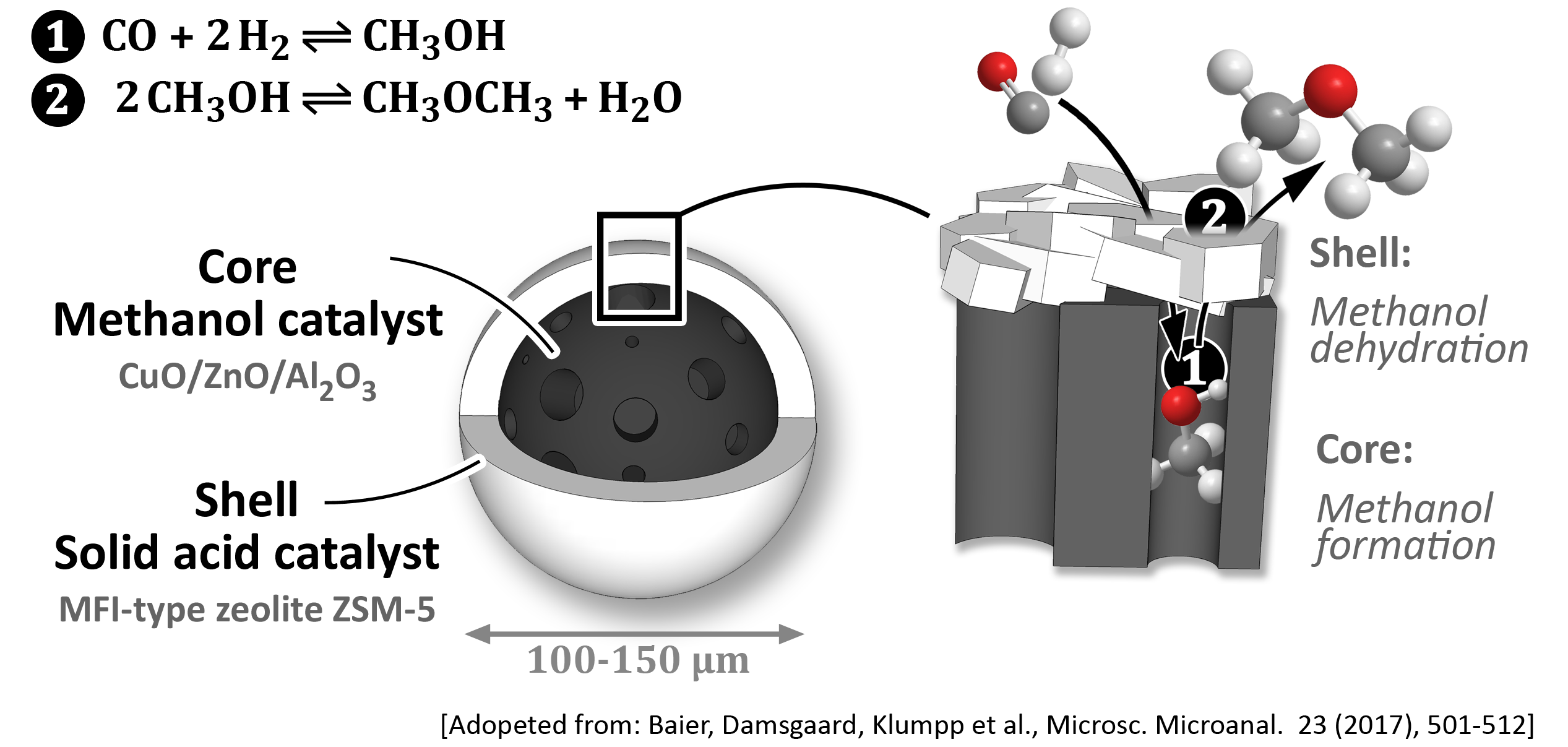

Novel bifunctional core@shell and double-layer catalysts for direct DME-synthesis in microstructured reactors

In the scenario of the energy transition, the conversion of renewable electricity into chemical energy carriers (e.g. hydrocarbons-based fuels) is widely discussed as a promising option for the energy storage by coupling different energy sectors via so-called power-to-X technologies. One possible route is the conversion of hydrogen (from water electrolysis using renewable electricity) together with CO and/or CO2 into dimethyl ether (DME) via methanol as an intermediate product. DME is for example an excellent and efficient alternative to fossil diesel fuel. As renewable electricity (PV or wind) usually is harvested spatially distributed and in small scale (as compared to conventional power plants), the conversion processes also have to be feasible in small scale and with high efficiency. In case of the DME-synthesis, the thermodynamics of the upstream methanol synthesis is the limiting factor. To overcome this limitation, the single-stage DME synthesis in microstructured reactors is a promesing concept: the rational combination of the both catalysts in one reactor - e.g. as bifunctional core@shell catalyst or double layer - allows to shift the MeOH synthesis equilibrium by its direct dehydration to DME which eventually leads to an enhanced COx-conversion and as a consequence to an enhanced process efficiency. The direct synthesis of DME from CO/H2-mixtures using different configurations of bifunctional catalysts is investigated within the frame of the DFG priority program 1570. The direct conversion of carbon dioxide/H2-mixtures to DME using rationally designed planar catalyst coatings in microstructured reactors is within the scope of a project funded by the Vector Stiftung.

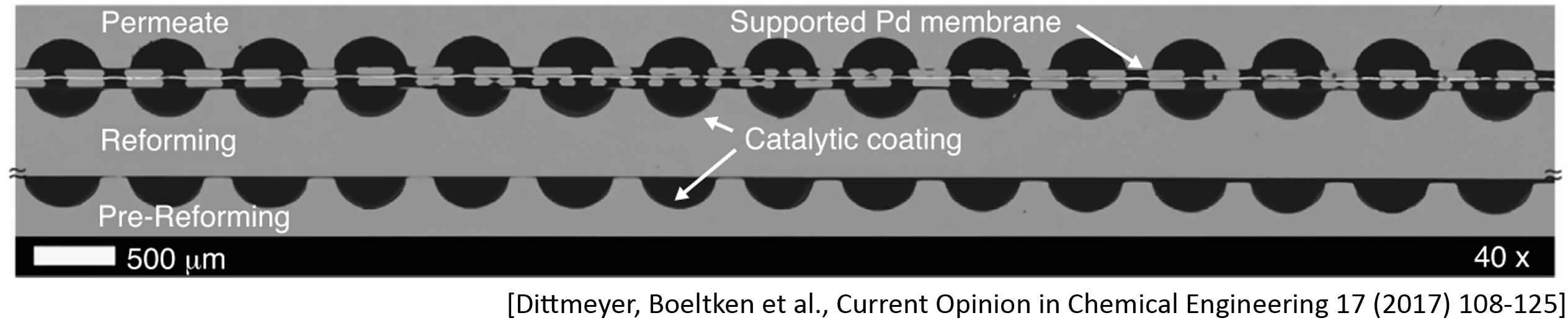

Combined catalyst and membrane integration for efficient hydrogen production

The group is working on the demonstration of an integrated reactor system for the efficient hydrogen production in small scale applications. Via the modular approach, with an integrated membrane pure hydrogen can separated from the MSR-product gas stream. As a consequence, the conversion of methane can be increased and an elaborated hydrogen purification can be avoided. In close cooperation with the Forschungszentrum Jülich and the German Aerospace Center, besides the continuous advancement of the membrane-integration, an intensive evaluation of the compact catalytic membrane reactor under realistic medium and long-term reforming conditions is planned.