Characterisation and Conditioning of Pyrolysis Products

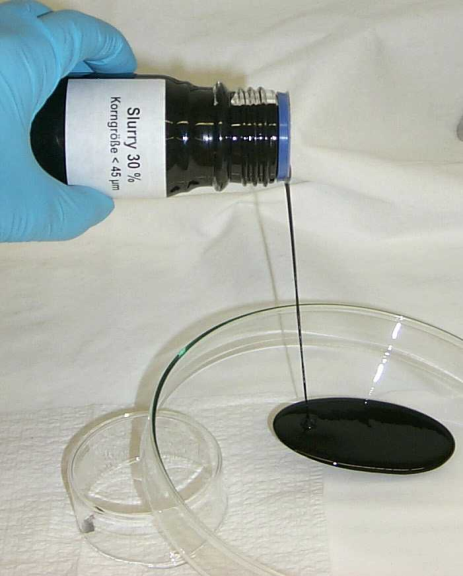

In the context of the bioliq project and the first pyrolysis process step the solid and liquid pyrolysis products are mixed together to a so-called Biosyncrude, a pumping-capable, solid-rich suspension of pyrolysis char and condensate. The Biosyncrude is converted in the High Entrained Flow Gasifier to synthesis gas which can be transformed into chemicals and fuels. For a fully conversion the chemical composition, the viscosity and the heat value have to be considered.

The pilot plant is laid out especially on grain straw as a feedstock. However, in laboratory and technical laboratory other organic feedstocks are also tested and other mixtures of pyrolysis products. In particular it is important to be ensure of the storage stability: Pyrolysis condensates are reactive mixtures and rich of polar organic substances. Moreover, the sedimentation must be considered. Alternative production and feed-in processes are investigated, e.g. with colloid mixers, kneaders, extruders and their individual, specific power demand.

The Biosyncrude made from pyrolysis products is still no standardised fuel, hence, any measurement has to be tested referring to the chemical and physical properties of the biosyncrude and adapted if necessary. Two feedlines are ready for it and can be - in those conventional, as well as innovative measuring instruments on their suitability examined and if necessary - adapted. The smaller feedline (10 kg of contents in the circulation) is suited particularly to the calibration with different compositions, while the bigger Feedlinie (1000 kg of contents in the circulation) checks the suitability in the continuous operation.

The chemical composition of pyrolysis condensates is extremely complicated because of different reasons: Nearly all components are highly polar, and nevertheless, pyrolysis condensates incline to a phase separation between water-soluble and organic-soluble components. Approx. half of the organic substances are monomers, the other half are aromatic oligomeres (the so-called pyrolysis lignin). The main problem of the chemical analytics is to find the middle course between the best possible characterisation of the specimen and a defensible amount of work involved. It is important, on this occasion to make a distinction between laboratory and process analytics. The laboratory analytics are entitled to higher precision and diversification, of the process analytics it is demanded that it works on a real-time basis and is limited to a few essential parametres.

Beside the use of the pyrolysis products as a Biosyncrude in the bioliq process one can fancy other uses, e.g. the combustion of pyrolysis char pellets and the chemical use of selected components of the pyrolysis condensates. We examine the chemical modification around the pyrolysis condenates for alternative, attractive uses. The aims of the modifications are e.g. the stabilisation (better storage), rise of the heat value and the synthesis of a special target molecule.