Institute of Catalysis Research and Technology (IKFT)

The Institute of Catalysis Research and Technology was founded 2011. Its mission is to bridge the gap between fundamental and applied research and the development of new technologies and products in the field of catalysis and process technology of catalyzed processes. The focus of our work is the sustainable utilization of alternative feedstocks and their conversion into energy carriers intermediates. This includes the development of new catalytic systems based on a fundamental understanding of processes on a molecular level. The institute receives basic funding from the Helmholtz Association's program-oriented funding, largely in the Energy research field in the program Materials and Technologies for the Energy Transition.

On February 25, Constantin Fuchs successfully defended his dissertation entitled “Synthesis of aromatic-free gasoline and kerosene by means of heterogeneously catalyzed (co-)oligomerization of methanol-based olefins.” The supervisors were Professors Jörg Sauer and Reinhard Rauch.

Congratulations!

more_rdax_98s.jpg)

On 21 November, the Night of Science took place at KIT, and IKFT contributed to the vibrant program.

more

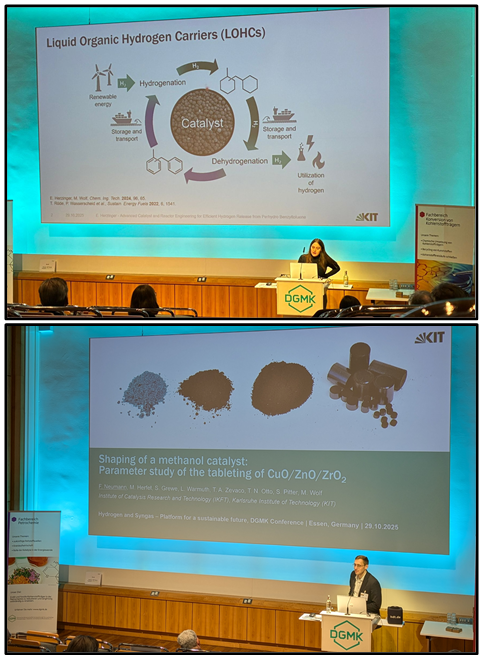

The DGMK event Hydrogen and Syngas - Platform for a sustainable future was jointly organized by the DGMK Divisions "Petrochemistry" and "Conversion of Carbon Carriers", the Division of Industrial Chemistry of the Società Chimica Italiana (SCI) and the ÖGEW Österreichische Gesellschaft für Energiewissenschaften.

more

The NFDI4Cat 2.0 kick off meeting took place on 22 and 23 October 2025 at the DECHEMA Haus in Frankfurt (Main). In this second funding period, TT-Prof. Dr. Moritz Wolf joins as a Participant and introduced his activities in data-driven research to the consortium. Together with the established principal investigator Prof. Dr. Olaf Deutschmann and Dr. Sofia Angeli IKFT will shape the future of catalysis-related data and research.

A large group of researchers from KIT attended the 16th European Congress on Catalysis (EuropaCat 2025) in Trondheim, Norway (31.08 to 05.09.2025). Professors, postdoctoral and doctoral researchers from IKFT, as well as ITCP and ITC, contributed with posters, oral presentations, and a plenary lecture, showcasing the catalysis research at KIT.

more

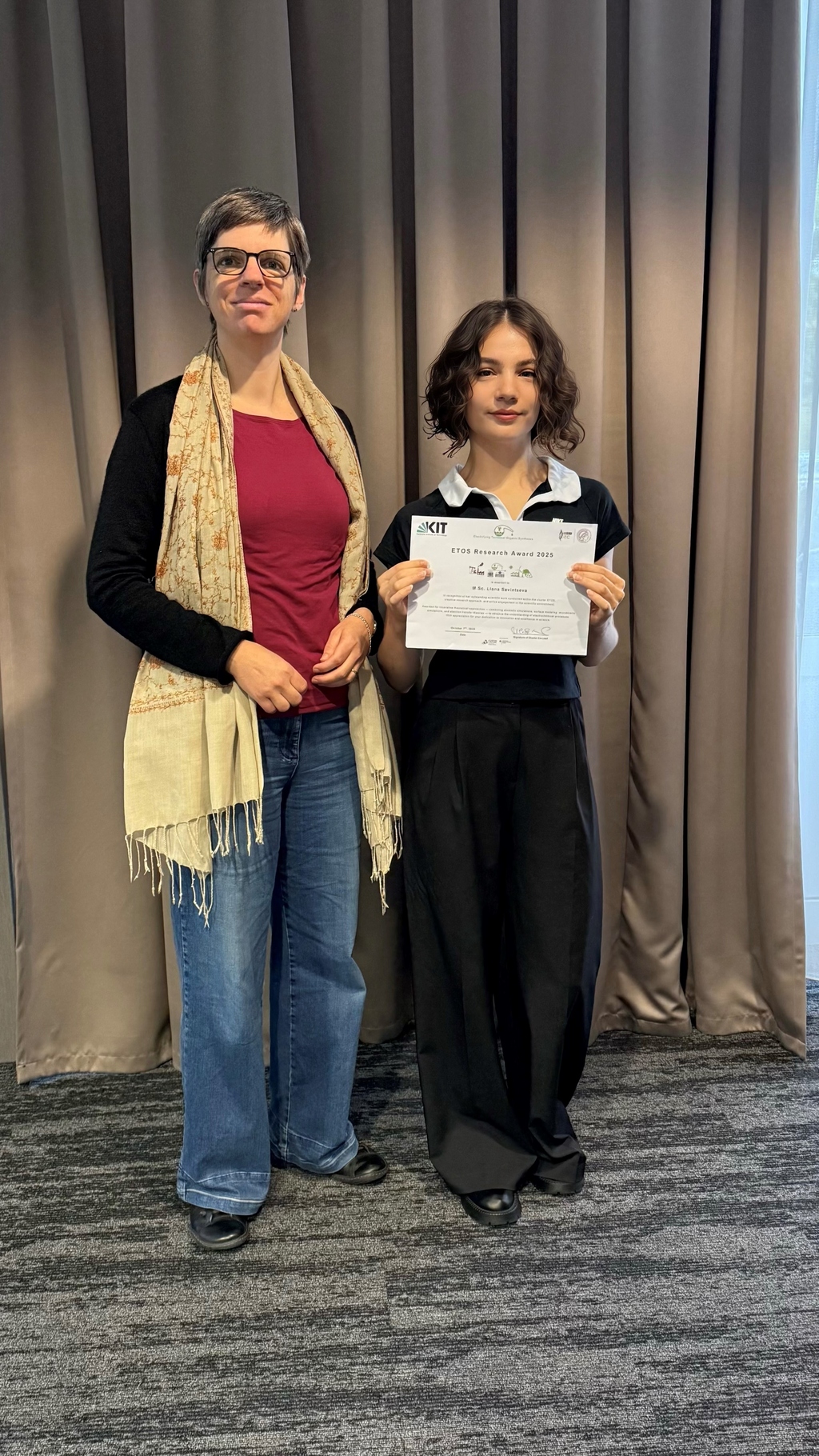

Liana Savintseva won the ETOS Research Award. Congratulations!