Hydrothermal Carbonisation

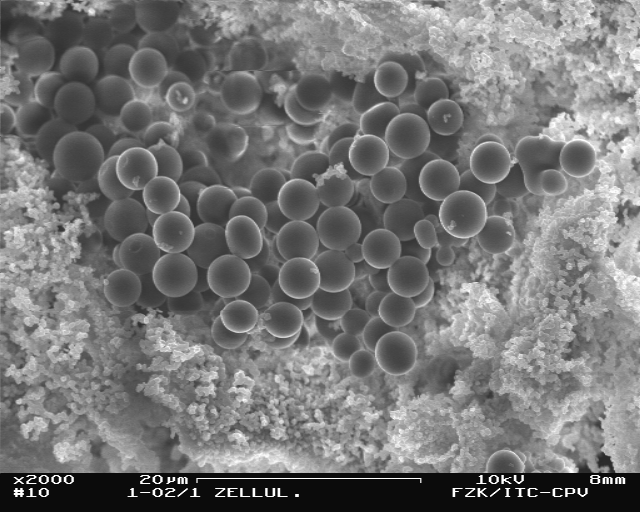

The Hydrothermal Carbonisation is a process which converts biomass in water or biomass with a high water content to a coal-like substance. The typical reaction conditions for Hydrothermal Carbonisation processes are 180-230°C with slightly raised pressure to prevent the evaporation of the water.

For the products gained from Hydrothermal Carbonisation processes ("HTC-coal") various possibilities of utilisation are suggested: On the one hand, HTC-coals can be used to improve the soil (analogously "Terra Preta": „black ground“, leads to fertile soil in the Amazon region) and as a brown coal substitute, as grill coal or catalyst carrier material. A later use of synthetic soot ("Carbon Black"), as it is seated as a black pigment dye or in tyre, seems possible and is very desirable on account of the high energy consumption of current processes. Now these different applications also require special properties of the HTC-coals. Thus a low ash and nitrogen concentration is desirable with the use as a fuel, but, however, by the use in the soil as long time fertilizers, the requested properties like high minerals and nitrogen concentration are desirable.

The aim of the research at IKFT is to understand Hydrothermal Carbonisation processes in order to produce suitable HTC-coals for the requested applications.

Literature

- E. Dinjus, A. Kruse, and N. Tröger,

Hydrothermal Carbonisation-1.Influence of Lignin in Lignocelluloses,

Chemical Engineering & Technology 34 (2011) 2037-2043. - A.Kruse, F. Badoux, R. Grandl, and D. Wüst,

Hydrothermale Karbonisierung: 2. Kinetik der Biertreber-Umwandlung/ Hydrothermal Carbonisation: 2. Kinetics of Draff Conversion,

Chemie Ingenieur Technik 84 (2012) 509-512