Nanoscaled Materials for Catalytic Processes

Transition metal nanoparticles represent important materials in catalysis, not only in fundamental studies but also in various processes of great industrial and societal relevance. Although even small improvements in the catalytic properties of these materials can have a large economic or ecological impact, the processes/mechanisms that occur on the surface and the nature of the active site are often not understood. However, a better understanding of these fundamentals is a prerequisite for a more rational design of catalysts with improved catalytic activity or selectivity. In this context, model catalysts with defined material properties can help to elucidate structure-property relationships.

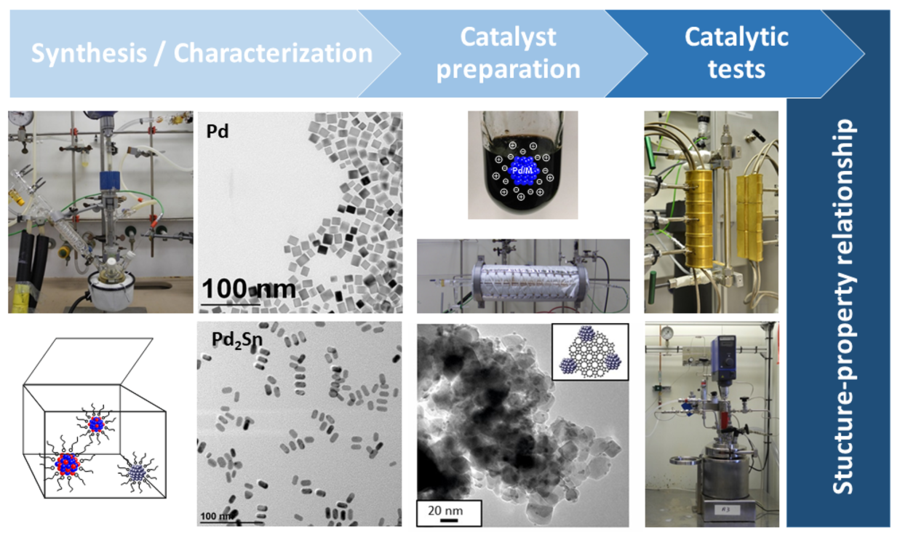

We develop nanoparticles with tailored properties which we use as precursors for the production of defined model catalysts (‘precursor concept’). The nanoparticles are usually immobilized on a support material to manufacture powder model catalysts. Alternatively, the nanoparticles may be also employed as quasi homogeneous catalysts dispersed in liquid carrier media (such as ionic liquids). Nanoparticle-based powder model catalysts may help to bridge the gap between fundamental surface science on single crystals and industrial application.

The development of high-quality nanoparticles and model catalysts requires a large repertoire of chemical synthesis methods which allow for the control of the material parameters. We make use of various synthesis strategies such as solvothermal, decomposition, polyol and reduction processes. We also exploit the specific physicochemical properties of ionic liquids to control nucleation/growth processes in the liquid phase and to stabilize nanoparticles by weakly coordinating anions/cations. We use various analytical tools to characterize the size, shape, structure and composition of our nanoparticles and catalysts, including electron microscopy (SEM, TEM, EDX), X-ray diffraction (XRD, SAXS), dynamic light scattering, FTIR, UV-vis and optical emission spectroscopy (ICP-OES) as well as classic surface sensitive methods (e.g. N2 pysisorption).

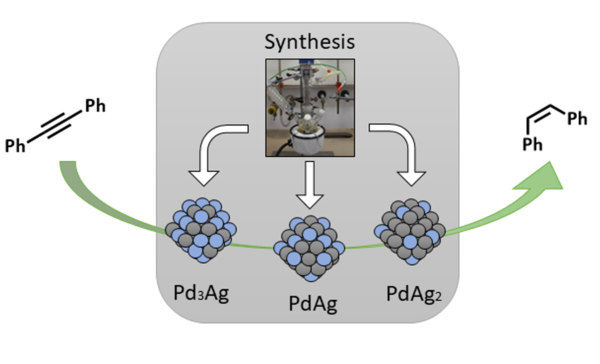

Figure 1. To study structure-properties-relationsships, we develop nanoparticles with tailored size, shape and composition and use them as precursors for manufacturing of model catalysts (precursor concept).

Our current focus is in particular on a better understanding of synthesis gas processes (one-step synthesis of dimethyl ether from synthesis gas (CO2/CO/H2) using bifunctional catalysts), selective hydrogenation of organic substrates in the liquid phase (quasi homogeneous catalysts in ionic liquids), and the direct synthesis of hydrogen peroxide from molecular hydrogen and oxygen. Here we operate various continuous, semi-continuous and batch reactors to study the catalytic properties as a function of different material parameters (size, shape, structure and composition). Within the framework of CRC 1441 „Tracking the Active Site in Heterogeneous Catalysis for Emission Control” we are also interested in the development of powder model catalysts for emission control.

Selected review article on this topic:

- D.I. Sharapa, D.E. Doronkin, F. Studt, J.-D. Grunwaldt, S. Behrens, Moving Frontiers in Transition Metal Catalysis: Synthesis, Characterization and Modeling, Adv. Mater. (2019), 31, 1807381

For further information see publications.

Functional Materials: Magnetic Nanoparticles and Hybrid Materials

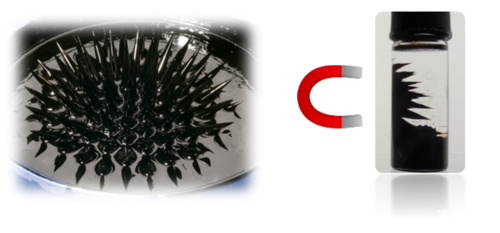

Soft materials that respond to external stimuli have attracted great interest in the fabrication of functional materials and smart systems. In particular, the hybridization of magnetic nanoparticles (MNPs) with isotropic and anisotropic organic matrices (technical oils and liquid crystals (LCs), respectively) opens new perspectives for the development of novel magnetoresponsive materials (e.g., ferrofluids, ferronematics) for various applications.

Figure 1. Examples of magnetic hybrid materials: Ferrofluid with typical Rosensweig-instabilities and magnetic catalyst separation.

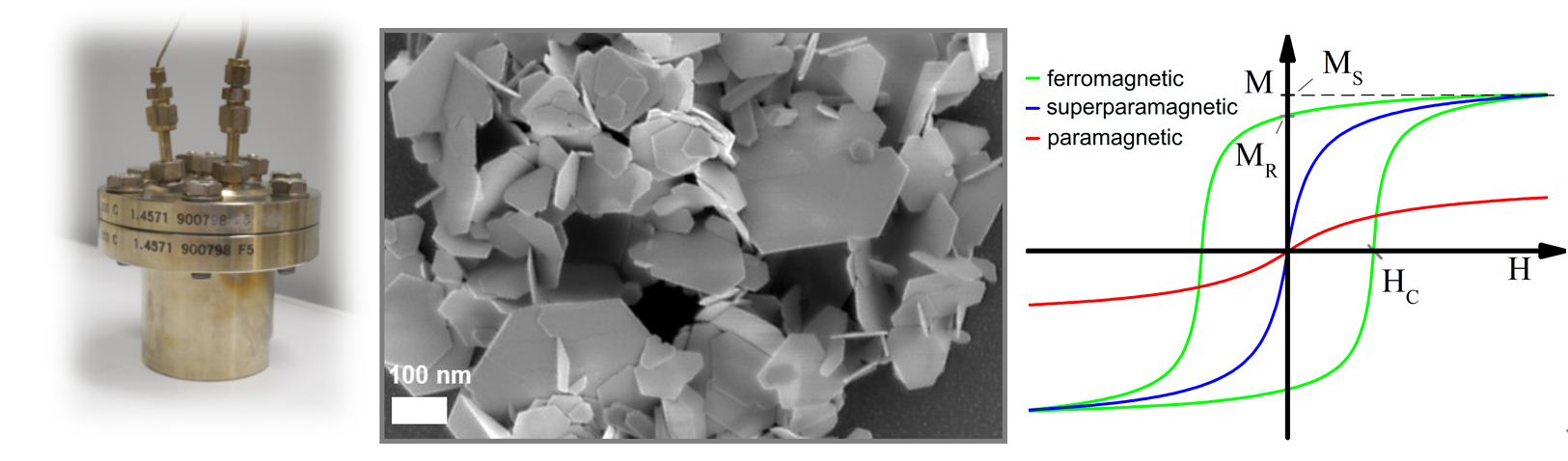

We develop nanoparticles of various inorganic magnetic materials (e.g. ferrites with spinel or magnetoplumbite structure, magnetic metals/alloys) with adjustable size and shape (spheres, rods, platelets etc.) and tailored magnetic properties by liquid phase syntheses (e.g. via solvothermal, decomposition, reduction or precipitation processes).

Figure 2. Synthesis of nanoparticles in liquid phase: Autoclave for solvothermal synthesis, hexagonal, Sc-doped BaFe12O19 platelets and typical magnetisation curves of a blocked ferromagnet, a paramagnet and a superparamagnet.

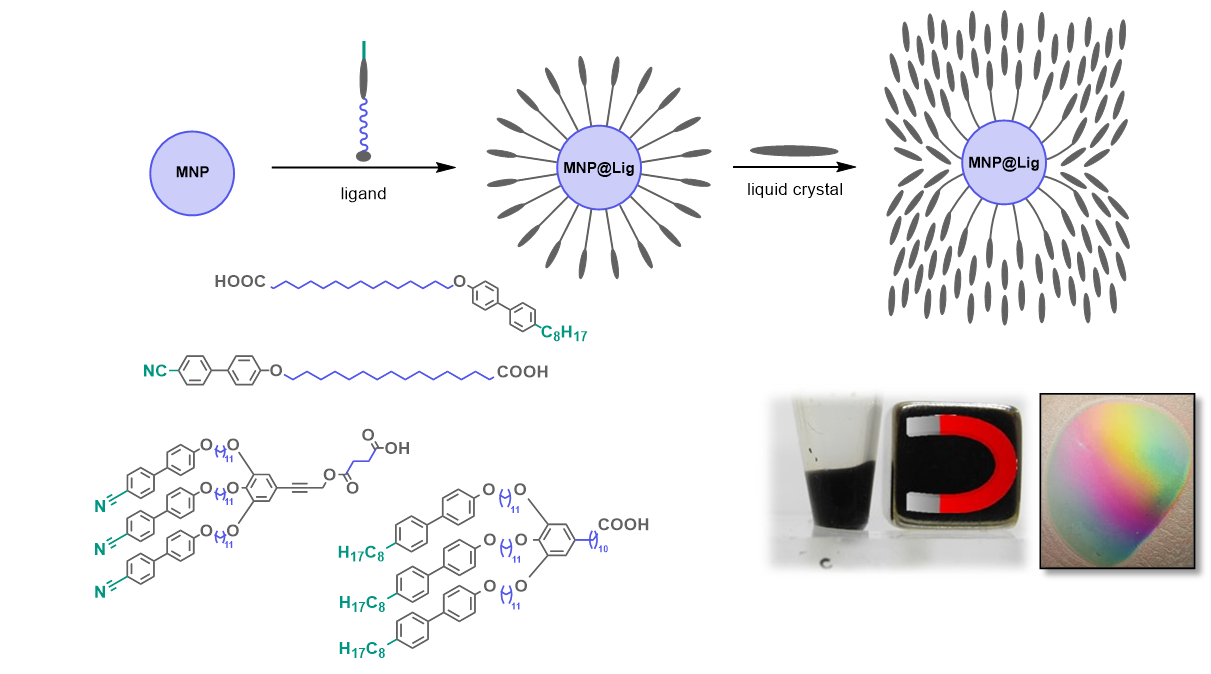

To prepare functional hybrid materials, these particles are successively stabilized in isotropic or anisotropic organic matrices (e.g. technical oils, LCs). LCs are characterized by combining the fluidity of ordinary liquids with anisotropic, optical properties of crystalline materials. The introduction of inorganic magnetic particles into LC matrices leads to elastic distortions of the director and/or perturbation of the local order parameter in the vicinity of the magnetic nanoparticles, resulting in LC-mediated interparticle interactions. Therefore, the surface properties of the magnetic particles must be specifically tailored to stabilize the nanoparticles in the LC matrix. These hybrid materials (ferronematics) reveal interesting optomagnetic and optoelectric properties.

Figure 3. Stabilization of magnetic nanoparticles in LCs and preparation of ferronematics require specific surface functionalization of the particles by (pro)mesogenic ligands. These ligands typically consist of three structural entities, i.e., a mesogenic unit and a functional group for binding to the magnetic particles, which are connected by a flexible linker. Shown is a ferronematic in 4-cyano-4‘-pentylbiphenyl (5CB) and modulation of the optical properties of a ferronematic in the magnetic field.

Selected review articles related to the topic:

- M. Hähsler, I. Appel, S. Behrens, Magnetic Hybrid Materials in Liquid Crystals, Phys. Sci. Rev. (2021), https://doi.org/10.1515/psr-2019-0090

- S. Behrens, I. Appel, Magnetic Nanocomposites, Curr. Op. Biotechnol. (2016), 39, 89 – 96

- S. Behrens, Preparation of Functional Magnetic Nanocomposites and Hybrid Materials: Recent Progress and Future Directions, Nanoscale (2011), 3, 877 – 892

For further information see publications.